High performance deflashing machines

High performance deflashing machines

for effective deburring of elastomers, plastics and zinc die-casts

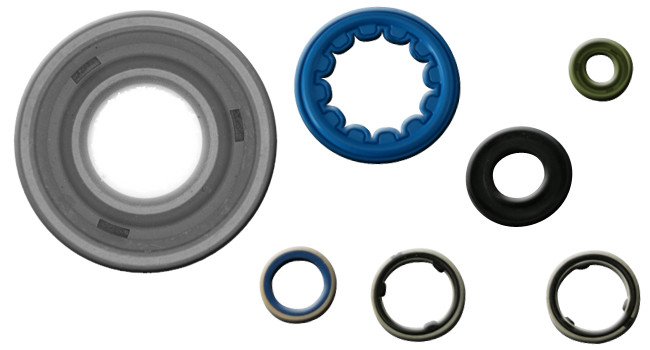

The process of deflashing

Low temperature liquid nitrogen will be injected in tiny drops on the moulded parts. During the conversion from liquid to gas state the extracted energy causes shock-freezing of the burrs reaching the embrittled condition as fast as possible. The actual molded parts will still remain elastic.

Any damage to the surface by flaking off due to the tension will be avoided. The shock frozen burr is not as solid as the actual moulded part and therefore it can now be removed by blasting media with high efficiency.

Parts recommended for deflashing:

• O-

•

•

•

•

E20

E20 Low-Temperature Deflashing Machine

Small size cryogenic machine for the deflashing of rubber parts, plastics and zinc die-casts suitable for molded arcticles from 3 to 150 mm.

This computer controlled machine offers high efficiency deflashing of rubber and plastic parts as well as zinc die-casts. With its small footprint, the E20 deflashing machine can be integrated into the production line easily and therefore avoids temporary storage or transports and corresponding time loss and costs. The E20 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on latest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network (support via internet), recipes memory, user administration, logging/documentation and barcode scanner/ID key.

On customers request, the E20 is also available with quick-exchange basket system.

Highlights:

• fast processing times (4 – 6 minutes) at 20 l drum volume

• network compatible (technical support via internet connection possible)

• recipes memory and fast and easy loading of your individual settings

• clear and comfortable touchscreen operation with barcode scanner, USB and SSD hard disk

• user administration: you determine authorisation and user restriction

• fast and easy user login via barcode scanner (ID card) or ID key possible

• logging/documentation of all parameters and users (exportable via LAN/USB, MS Excel compatible data)

• all motors and gears outside the freezing area

• working level (peak) below 80 dB(A)

• machine optional available with quick-exchange basket system

E30

E30 Low-Temperature Deflashing Machine

Small size cryogenic machine for the deflashing of rubber parts, plastics and zinc die-casts suitable for molded arcticles from 3 to 150 mm.

This computer controlled machine offers high efficiency deflashing of rubber and plastic parts as well as zinc die-casts. With its small footprint, the E30 deflashing machine can be integrated into the production line easily and therefore avoids temporary storage or transports and corresponding time loss and costs. The E 30 is, like any of our machines, designed for high performance at low consumption of nitrogen, blasting media and electric energy. The comfortable operator features on latest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network (support via internet), recipes memory, user administration, logging/documentation and barcode scanner/ID key.

On customers request, the E20 is also available with quick-exchange basket system.

With this machine, your treatment capacity in cryogenic finish treatment are at best cost/performance ratio!

Highlights:

• fast processing times (4 – 6 minutes) at 30 l drum volume

• network compatible (technical support via internet connection possible)

• recipes memory and fast and easy loading of your individual setting

• clear and comfortable touchscreen operation with barcode scanner, USB and SSD hard disk

• user administration: you determine authorisation and user restriction

• fast and easy user login via barcode scanner (ID card) or ID key possible

• logging and documentation of all parameters and users (exportable via LAN/USB, MS Excel compatible data)

• all motors and gears outside the freezing area

• working level (peak) below 80 dB(A)

• machine optional available with quick-exchange basket system

E40

E40 Mid-Sized High Performance Low-Temperature Deflashing Machine

High performance cryogenic machine for the deflashing of rubber parts, plastics and zinc die-casts suitable for molded arcticles from 3 to 300 mm.

This computer controlled machine offers high efficiency deflashing of rubber and plastic parts as well as zinc die-casts and is with its 40 litre drum volume designed for medium demands. The E40 is, like any of our machines, conceptualized for high performance at low consumption of nitrogen, blasting media and electric energy. The easily accessed exchangeable filter system allows a fast cleaning procedure as well as an easy exchange of filters if required. The comfortable operator features on latest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network (support via internet), recipes memory, user administration, logging/documentation and barcode scanner/ID key.

Highlights:

• fast processing times (4 – 6 minutes) at 40 l drum volume

• network compatible (technical support via internet connection possible)

• recipes memory and fast and easy loading of your individual settings

• clear and comfortable touchscreen operation with barcode scanner, USB and SSD hard disk

• user administration: you determine authorisation and user restriction

• fast and easy user login via barcode scanner (ID card) or ID key possible

• logging/documentation of all parameters and users (exportable via LAN/USB, MS Excel compatible data)

• all motors and gears outside the freezing area

• working level (peak) below 80 dB(A)

• with exchangeable filter system

E90

E90 Big-Sized High Performance Low-Temperature Deflashing Machine

High performance cryogenic machine for the deflashing of rubber parts, plastics and zinc die-casts suitable for molded arcticles from 3 to 500 mm.

This computer controlled machine offers high efficiency deflashing of rubber and plastic parts as well as zinc die-casts and is with its 90 litre drum volume designed for big demands. The E90 is, like any of our machines, conceptualized for high performance at low consumption of nitrogen, blasting media and electric energy. The easily accessed exchangeable filter system allows a fast cleaning procedure as well as an easy exchange of filters if required. The comfortable operator features on latest level leave no wish unfulfilled: touchscreen operation, USB/SSD hard disk, network (support via internet), recipes memory, user administration, logging/documentation and barcode scanner/ID key.

This machine type offers the highest level of article-flexibility and economic efficiency in cryogenic deflashing treatment!

Highlights:

• fast processing times (4 – 6 minutes) at 90 l drum volume-network compatible (technical support via internet connection possible)

• recipes memory and fast and easy loading of your individual settings

• lear and comfortable touchscreen operation with barcode scanner, USB and SSD hard disk

• user administration: you determine authorisation and user restriction

• fast and easy user login via barcode scanner (ID card) or ID key possible

• logging/documentation of all parameters and users (exportable via LAN/USB, MS Excel compatible data)

• all motors and gears outside the freezing area

• working level (peak) below 80 dB(A)

• with exchangeable filter system

Blasting Media Recovery Systems

Blasting Media Recovery Machine

Complete suction and drying system for recovering of the blasting media that is used in our deflashing machines for recirculation.

Due to abrasion, the blasting media becomes more and more polluted by rubber and plastic powder. Thus the performance and the processing time of the blasting media can change. In our deflashing machines, the blasting material is filtered by the perforation of the drum, however, after a long operating time the amount of powder increases. In order to guarantee constant and efficient processing, the powder has to be removed from the blasting media.

Our automatically working recovery machine consists of a suction and drying system and vibrating filter. The used media has to be aspirated manually from the deflashing machine. The polluted, wet and cold media will be dried in the suction tank and then cleaned by the filter. There will be a separation into powder, crushed media and usable media. The drying and cleaning process takes about 3 to 4 hours.

Highlights:

• re-use of worked up blasting media (>>suctioning >> drying >> cleaning >> separating)

• cutting costs by the re-usage of used media and therefore reducing the consumption of new blasting media

• optimal deflashing results by constant jet pattern due to consistent blasting media mixture (mixing ratio old and new granulate)

• mobile use possible due to low self-weight

• comfortable touch panel operation for all parameters