KTprime

Modular Performance Inspection System:

For the part dimensions of 5 – 40 mm, our single/double glass table inspection system KTprime/KTprime²is available, equipped with different sensors modules for dimension and surface control.

Typical parts for automatic inspection are almost all round-symmetric seals like o-rings, cuffs, v-seals but also flat seals, mainly of rubber, plastic, ceramic or small metals parts.

KTprime is a single glass-table-system which enables the installation of sensors from the bottom to scan through the glass-plate-table. This allows an inspection of both sides of the parts on one glass-plate. Therefore, this system is the ideal solution for economic standard requirements with low budget expenditure.

KTprime² is a double glass-table system for high requirements. By the arrangement of two glass-table modules linked with a turnover unit, a double-side inspection from above fulfills higher demands without having the optical limitations caused by a scan through the glass table.

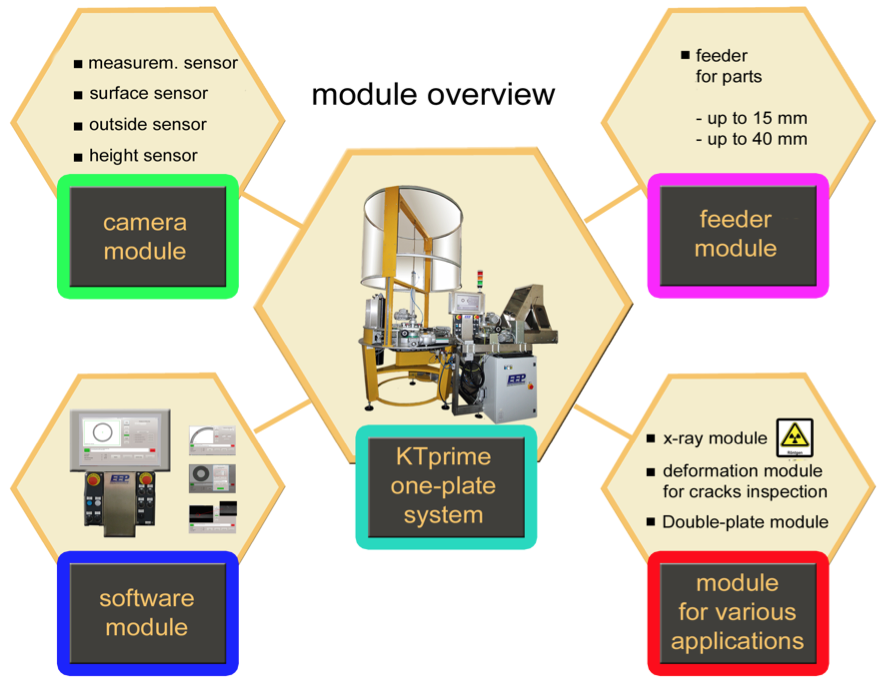

KTprime can be configured with several modules according to customer needs:

Up to 6 KTsensors can be installed in arbitrary order on the basic machine.

A stable engineering for optimized flow of parts form the backbone for sensor and actuator systems. Easy access allows rapid conversion to other parts as well as quick cleaning. The modular design allows easy configuration and upgrades, therefore, the KTprime inspection system offers a high degree of flexibility and customization options in accordance to particular (also retrospective) individual requirements and needs.

This system is designed as a plug and play system and thus ready for use in general without any specific knowledge.

The KTprime system is also available in a clean room version on your detailed request.

For your project inquiries please send us your details. We will start to analyse and prepare your quotation. It is important to have all the relevant information to provide you the best solution. Please use our project-request form.