KTwave

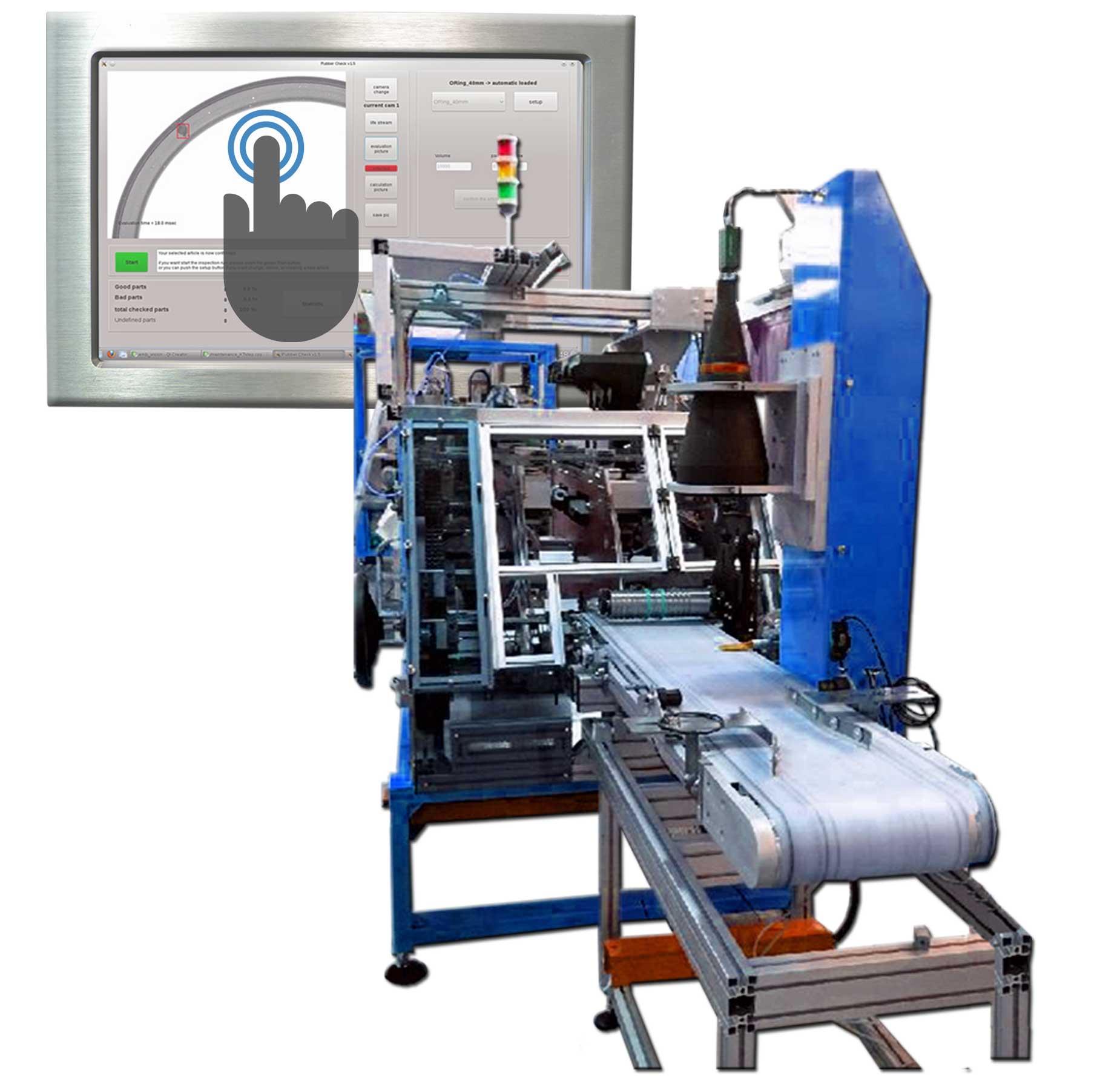

KTwave is especially designed for bigger o-rings within 80 – 250 mm, with high part throughput. For this range, a new approach has been chosen. The parts are picked up and then slightly stretched during the inspection process.

On a small foot print, seals can be examined economically with high quality. Due to the innovative arrangement and combination of the KTsensors, very economic inspection times can be achieved. The parts are automatically added and removed; the system can be loaded either manually or by a feeder unit. A rapid conversation to other parts and a quick cleaning ability are also given.

>> Product Brochure KTwave

During the rotation, each 4 cameras examine the complete surface. An additional module, inserted between feeder unit and inspection machine, is available for the diameter inspection up to an OD of 120 mm.

Innovations in detail and highest optical precision are generating detailed pictures of the parts. Multi-level lighting systems offer the highest possible contrast and thus a safe and reproducible surface analysis. All sensors are equipped with their own computing power and work autonomously. Only the results and the test instructions are exchanged via a network to the control computer.

For your project inquiries please send us your details. We will start to analyse and prepare your quotation. It is important to have all the relevant information to provide you the best solution. Please use our project-request form.